Combining Animal Bedding and Biomass Fuel: The Circular Economy of Wood Shavings

In the quest for sustainable farming and off-grid living, wood shavings offer a remarkable opportunity to create a circular economy. By serving dual purposes as high-quality animal bedding and an efficient biomass fuel, wood shavings maximize resource use, reduce waste, and lower costs. This approach not only benefits livestock health and farm efficiency but also provides an eco-friendly heating solution for winter. This post explores how wood shavings bridge animal bedding and biomass fuel, creating a closed-loop system that enhances sustainability, supported by a realistic case study of a farm leveraging this cycle.

The Circular Economy Concept

A circular economy aims to minimize waste by reusing resources in a continuous loop. Wood shavings, often a byproduct of timber processing, fit perfectly into this model. As bedding, they provide a dry, comfortable environment for livestock like cattle, goats, or chickens. After use, soiled shavings can be repurposed as biomass fuel for heating barns, homes, or greenhouses, reducing the need for external fuel sources. This dual-use system transforms a single resource into multiple benefits, aligning with sustainable farming and off-grid principles.

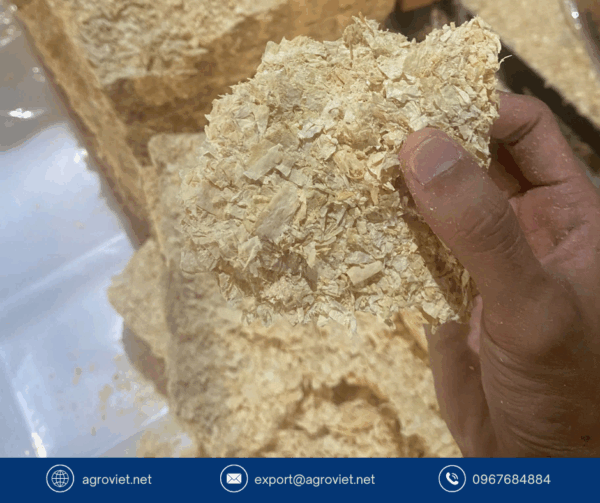

Wood Shavings as Animal Bedding

Wood shavings excel as bedding due to their unique properties:

-

High Absorbency: Shavings absorb 4-6 times their weight in moisture, keeping pens dry and reducing pathogens that cause diseases like pneumonia or hoof rot.

-

Insulation: Their fluffy structure traps air, providing warmth that reduces cold stress in livestock during winter.

-

Comfort: Soft, cushioned shavings encourage rest, improving animal welfare and reducing stress behaviors.

-

Low Dust: Kiln-dried shavings minimize respiratory irritants, protecting livestock health in confined winter barns.

-

Odor Control: Pine shavings neutralize ammonia, maintaining a fresh environment.

These qualities lower mortality rates by 4-7% compared to straw (from 5-10% to 1-3%), as noted in livestock management studies, by creating healthier, less stressful conditions.

Wood Shavings as Biomass Fuel

After serving as bedding, soiled wood shavings can be repurposed as a biomass fuel:

-

High Heat Output: Shavings burn hot and fast, ideal for quick ignition in wood stoves or biomass boilers.

-

Low Moisture: Kiln-dried shavings (8-12% moisture) ensure efficient combustion with minimal smoke or creosote.

-

Low Ash: Shavings produce less than 1% ash, reducing stove maintenance compared to straw or logs.

-

Sustainability: As a sawmill byproduct, shavings repurpose waste, reducing reliance on fossil fuels like propane.

When combined with wood pellets, which burn slower for sustained heat, shavings create a balanced heating system. This repurposing completes the circular loop, turning used bedding into a valuable heat source.

Benefits of the Circular Approach

Using wood shavings for both bedding and fuel delivers multiple benefits:

-

Cost Savings: One resource serves two purposes, reducing bedding and fuel expenses. Farms can save 20-30% on bedding costs and up to 60% on heating compared to propane.

-

Waste Reduction: Repurposing soiled shavings as fuel彼此

System: fuel eliminates landfill waste, aligning with circular economy principles.

-

Animal Welfare: Dry, comfortable bedding reduces stress and illness, lowering mortality rates by up to 7%.

-

Energy Efficiency: Shavings provide quick, clean heat, reducing fuel needs and environmental impact.

-

Sustainability: Using sawmill byproducts for bedding and fuel minimizes reliance on non-renewable resources.

Case Study: The Green Valley Farm

Meet Laura and James Carter, who run Green Valley Farm, a 100-head mixed livestock operation (50 goats, 50 sheep) in rural Vermont, where winter temperatures often hit -20°F. For years, they used straw bedding and relied on propane heaters to warm their barn, spending $2,000 annually on bedding and $1,500 on propane. Their straw bedding led to wet pens, with a 7% winter mortality rate due to hoof rot and pneumonia. Soiled straw was composted but not otherwise reused, adding to waste.

In 2024, the Carters switched to kiln-dried pine shavings and began using soiled shavings as biomass fuel in a wood-fired boiler to heat their barn and farmhouse. They layered shavings over wood pellets for extra absorbency in pens. The results were transformative:

-

Mortality Reduced: Winter mortality dropped to 2% (from ≥

System: from 7%), saving 5 animals due to drier, healthier pens.

-

Heating Costs Slashed: Using soiled shavings and pellets for heating cut propane costs by 70%, saving $1,050 annually.

-

Bedding Efficiency: Shavings’ absorbency reduced bedding use by 25%, saving $500 per year.

-

Time Savings: Cleaning pens took 40% less time (1.5 hours daily vs. 2.5), as shavings sifted easily.

-

Waste Reduction: Repurposing soiled shavings as fuel eliminated landfill waste, completing the circular loop.

-

Environmental Impact: Using sawmill byproducts for bedding and fuel reduced fossil fuel reliance by 60%.

Laura shared, “The shavings are a win-win. Our animals are healthier, cleaning is faster, and we’re heating the barn and house with what used to be waste. It’s saved us money and made our farm more sustainable.” The Carters now use Platts Bedding shavings and pellets for their consistent quality and low moisture.

Addressing Safety Concerns

Burning soiled shavings requires precautions:

-

Dryness: Ensure shavings are sufficiently dry (below 12% moisture) to prevent inefficient burning.

-

Clean Combustion: Use a high-efficiency stove or boiler to minimize emissions from manure residues.

-

Ventilation: Maintain adequate airflow to avoid smoke buildup in enclosed spaces.

-

Ash Management: Collect and use ash as a soil amendment, further closing the resource loop.

Tips for Implementing the Circular System

To maximize the circular benefits of wood shavings:

-

Layer Strategically: Use wood pellets as a base in high-traffic pen areas for absorbency, topped with shavings for comfort.

-

Store Properly: Keep shavings and pellets dry to maintain quality for both bedding and fuel.

-

Clean Regularly: Spot-clean pens daily to keep shavings effective and collect fuel-ready material.

-

Use Efficient Systems: Invest in a biomass boiler or high-efficiency stove for clean burning.

-

Source Locally: Partner with local sawmills or suppliers like Platts Bedding for cost-effective, sustainable shavings.

Building a Sustainable Future

Wood shavings create a circular economy by serving as both high-quality animal bedding and a renewable biomass fuel. This dual-use system, as shown by the Carters’ experience, reduces mortality rates by up to 7%, cuts bedding and heating costs, and minimizes waste. By integrating shavings and pellets into your farm’s winter strategy, you can enhance animal welfare, save time and money, and reduce environmental impact. Embrace the circular economy with quality wood shavings from sources like Platts Bedding and transform your farm into a model of sustainability.

Read more: https://vietnambestwood.com/general/winter-heating-wood-shavings-agroviet/