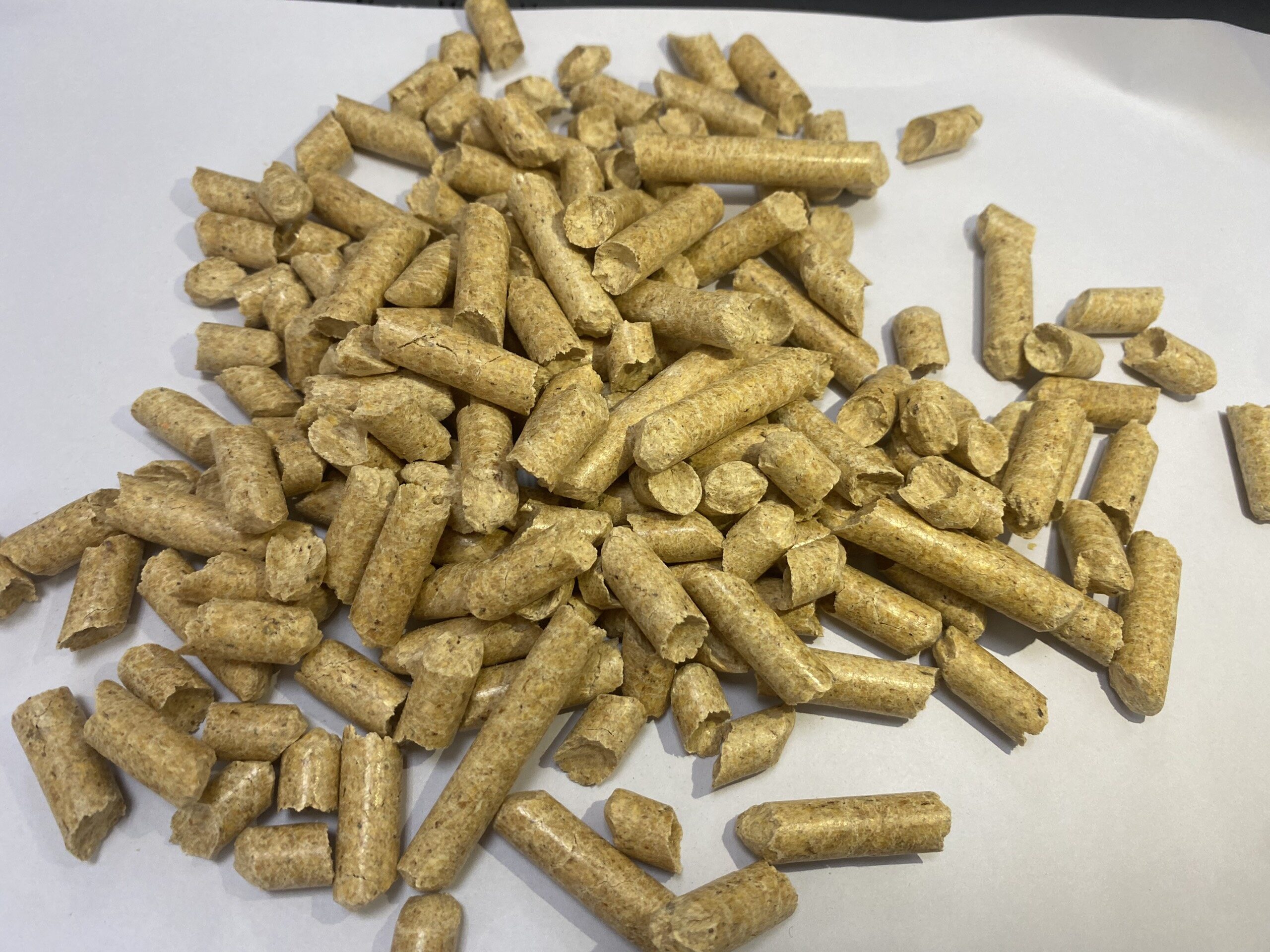

Rice Husk Pellets are a type of fuel that burns entirely from plants – specifically rice husks, so they are considered 100% green fuel. Rice husk is a byproduct of rice processing, its weight can be up to 20% of the weight of rice. Pelletized rice husks do not have toxic fumes and sulfur gases during the burning process that pollute the environment. Therefore, rice husk pellets can be a good substitute for coal, helping to save money, be economically effective as well as protect human health.

ADVANTAGES OF USING RICE HUSK PELLETS

Compressed rice husk pellets have a small volume so they burn easily, easily obtain high heat, and burn longer than rice husks. After being pelleted, the burning rate of rice husk can be over 95%. It has a pleasant aroma so it is very popular with consumers while the price is cheap, helping manufacturing businesses save huge fuel costs and bring optimal profits.

Easier to preserve. When rice husks are formed into pellets, the density of rice husks is significantly improved, making storage in large quantities more convenient.

It is a clean energy source, does not pollute the environment and is a sustainable renewable energy source.

At the same time, using rice husk pellets can be transported very conveniently due to the small product size.

Rice husk pellets burn cleaner. When burned directly, the ash content of rice husks is about 15-16%, while the ash content of rice husk pellets is only about 6-7%. Next we will compare the parameters of rice husk and rice husk pellets.

APPLICATIONS OF RICE HUSK PELLETS

1. Livestock farming

Lining animal cages and farms: chickens, horses, cows, hamsters, rabbits,…

2. Industry

Replace DO and FO oil: save more than 60% fuel costs.

Replace charcoal.

Replace coal: you can immediately use a coal-burning furnace without changing the original design, saving more than 40% on fuel costs.

Replace gas.

Replace electricity (in devices that use electrical energy sources).

3. Civil

Hot water tanks, water networks for amusement parks, restaurants, hotels, schools, rehabilitation areas,…

Cooking systems, kitchens in restaurants, hotels, etc.

Sauna system, massage,..

4. Electricity

Used as fuel in thermal power plants.

COMPRESSING AND PACKAGING PROCESS

Rice husk pellet production technology follows an automatic, closed chain from importing raw rice husks to finished products.

Rice husks are put into a tank to be ground into rice husk powder, then transferred to a high-pressure compressor to be pressed into pellets.

Continue to pass through the dust filtration and cooling system to form solid rice husk pellets for packaging. Rice husk pellets are neatly stacked in 35 – 50 kg PP bags, this is the optimal weight to facilitate loading and unloading by boiler workers during operation.

The bag is securely sewn so that the quality of rice husk pellets is always guaranteed during the process of loading, unloading and storing in the warehouse.

Depending on the price of raw materials and different times, rice husk pellets will have different prices, however, VBW always has raw materials and is stocked in large quantities, so our company’s rice husk pellet price policy is I am always stable to help businesses feel secure in using our rice husk pellets.